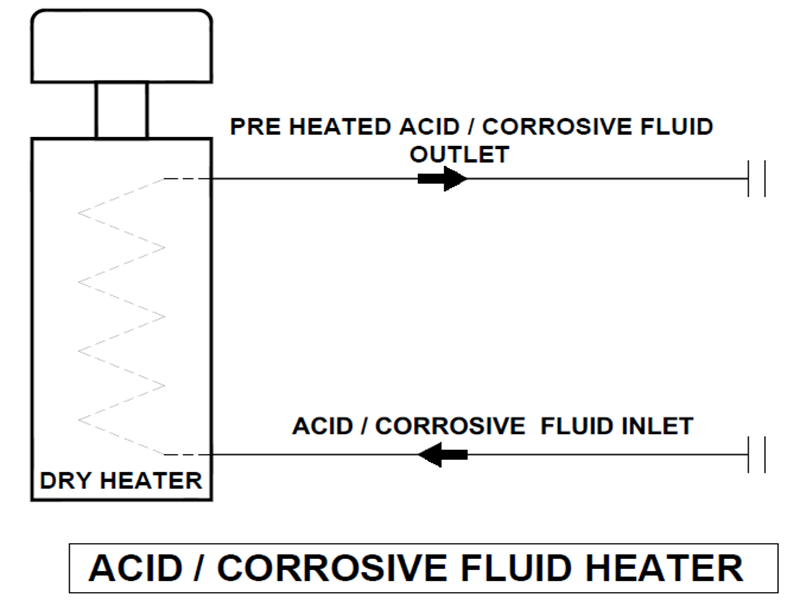

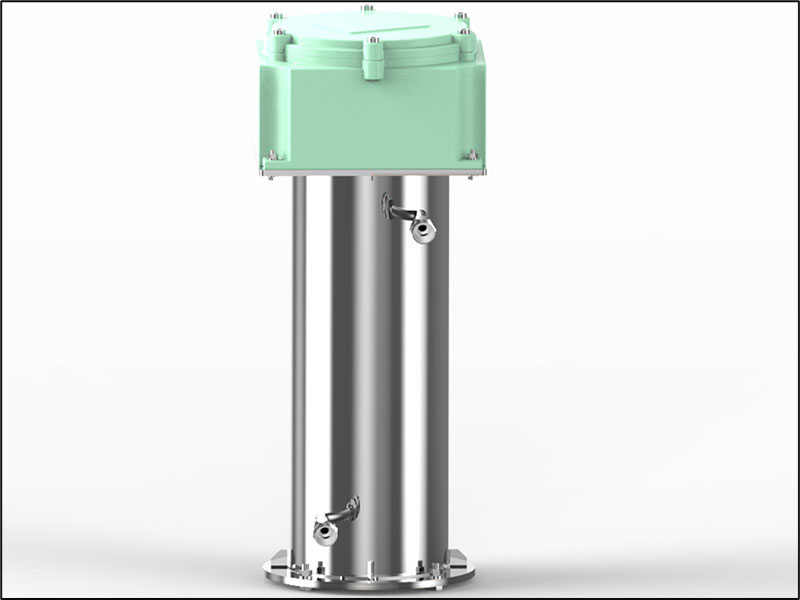

IEC Dryheaters can come with flow paths in Hastelloy or titanium which is suitable for heating of corrosive fluids such as acids.

Heated acid reacts at a faster rate and aids in removal of acid-retarding materials such as oil, asphaltene and paraffin’s from the formation to give a better acid-to-formation contact. Some other benefits of heating acid are:

1. Helps prevent precipitation of organic materials from oils that have been cooled by acids.

2. Limits the amount of tubing contraction due to temperature change.

Our Dry Heaters haave unique designs features, which includes isolated fluid paths and compatibility with caustic fluids or acidic fluids. Compared to traditional immersion heaters, our heaters can be mounted on-line in a pipeline without the necessity of a heating bath. With an immersion heater, if the heater fails the debris can end -up in the fluid path: with DryHeaters isolated fluid path, this is impossible, even if the heater element fails.

Our DryHeaters have the ability to heat many of the caustic chemicals associated with chrome and nickel plating applications.