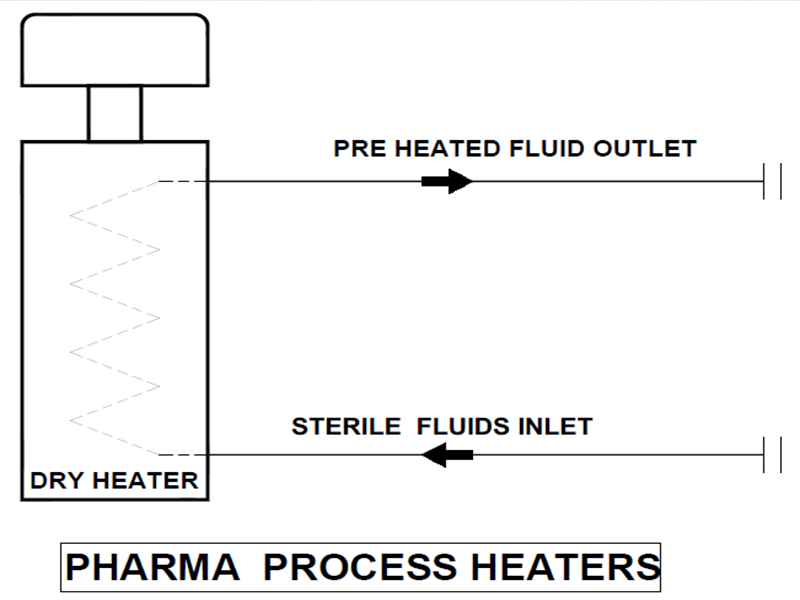

The Dryheater can be used to heat high-volume heating of liquid ingredients and sterile fluids used in biopharmaceuticals and other medical ingestible. Some of the pharma-medical applications are heating of diluted solvents and per-acetic acid for disinfection and pathogen elimination applications and heating applications used in the processing of plasma-derived and recombinant therapies.

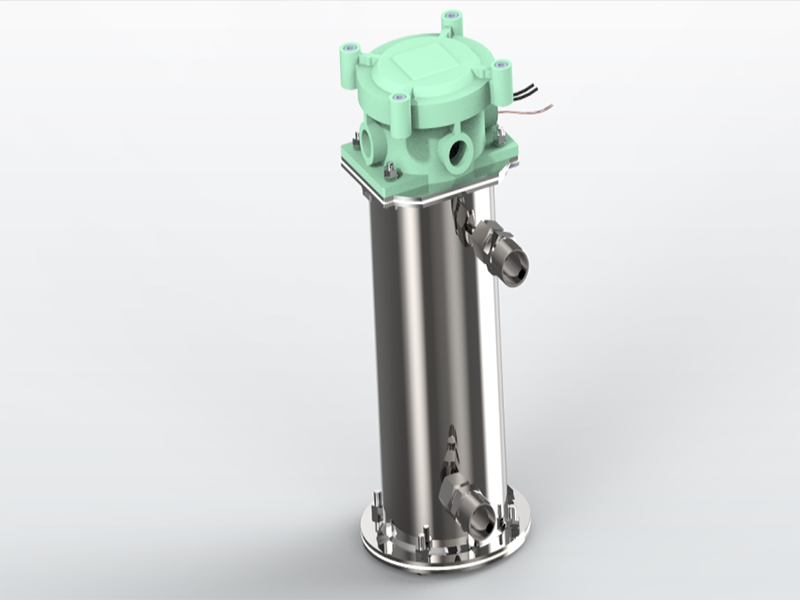

The primary design of the Dryheater is the stainless steel flow tube where heated media is isolated in this ultra clean tube that never contacts the heating element or any other portion of the heater. The flow tubes may be electro-polished and/or passivated to meet specific requirements. They can be used as an inline heaters and circulation heaters for contamination-free heating of liquid ingredients used in process fluids & medicines.

The Dryheater are installed to heat as inline heater or as a part of any recirculating loops it integrates well with all the fluid handling systems even for high purity pharmaceutical additives.

The Dryheater is very well suited to high-volume bio-pharmaceutical processing and various manufacturing. They are available in 5 various models with power ranging from 1.5 kW to 45 kW and multiple options for various Materials of construction of flow tubes customized according to the application and customer’s requirements.