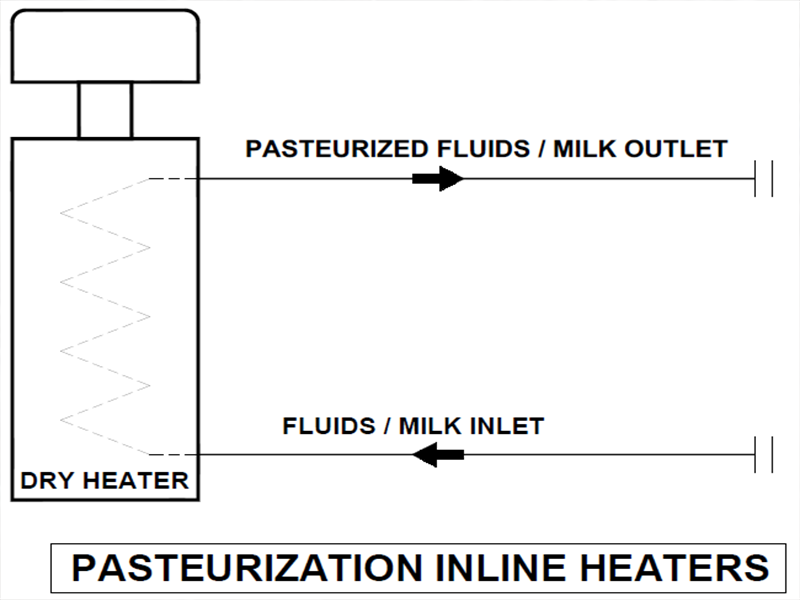

Heaters play an important role in food and dairy industries especially for the pasteurization process. For food & dairy processing, contaminants must be eliminated and this where the Dryheaters stands out over the traditional immersion heaters. If the immersion heater fails, the resulting debris may mix with the food and contaminate it and the entire process.

In addition, the flow tubes are sanitary-polished and passivated that helps the Dryheater deliver high purity output.

Our heaters can deliver high heat, purity and flow rates necessary for integration into pasteurization systems and various other liquid ingredient processing applications in food & dairy industries. Ultra-high-temperature (UHT) pasteurization which involves heating milk or cream to 138–150 °C for a period of 1 to 2 seconds followed by rapid cooling.

The heated liquids are isolated in the flow tubes; the heated media has no contact with the heating elements, sensors or other components, isolating the process liquid also minimizes the exposure of air, minimizing the risk of contamination. The flow tubes of our Dryheaters can be electro-polished to meet food and sanitary standards.