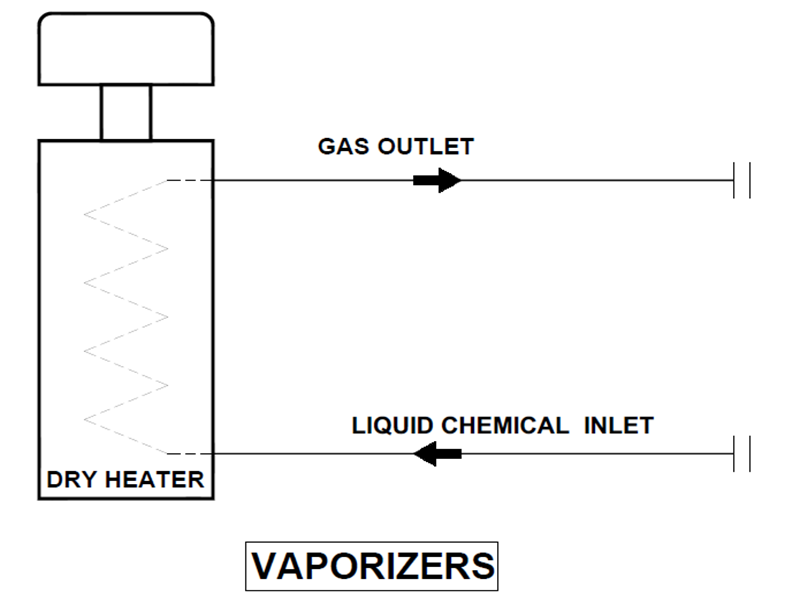

Vaporizers are heat exchangers or evaporators which transfer heat and bring a phase change from liquid to vapour by transferring thermal energy. The external source may be steam or electric heat.

Vaporizers are used in almost every process industries. Though conventional steam heated vaporizers and electrical heated vaporizers are available the operating pressure, steam requirement, low outlet temperature, low outlet pressure, freeze control, ice formation and hold up space of the vaporizers are the major drawbacks in these types of vaporizers.

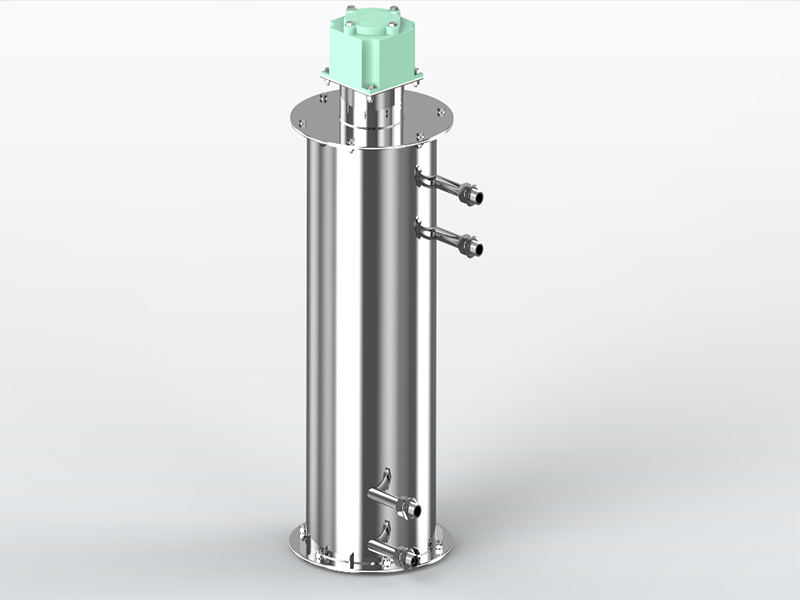

Dryheater will be the best alternative eliminating these shortcomings from the conventional vaporizers and can act as efficient electric vaporizers. The major advantages of the Dryheater over the conventional type of vaporizers are

- Higher efficiency due to higher temperature difference

- High pressure cryogenics can be safely vaporized

- Low footprint

- Robust construction

- Less susceptible to freeze-up and liquid entrainment

- Flame and explosion proof connections

The Dryheater is versatile and can be offered specifically to be used vaporizing various process fluids like,

- Ammonia

- Chlorine

- Tri-methyl amine

- Di-methyle amine

- Tri-fluoro acetyl chloride

- C3-C6 Hydrocarbons (including LPG)

- Carbon Dioxide

- Di/Trichlorosilane

- Alcohols

- Silicon Tetrachloride

- Sulphur Dioxide