TECHNOLOGY

The DRYHEATER is a heating equipment which transfer heat via electric heaters to a circulating process gas or liquid. It differs from conventional heaters in a few ways which prove to be highly advantageous.

1. The heating element does not come into direct contact with the process fluid. This feature eliminates the risk of contamination of the process fluid with compounds from the heating element. This feature is advantageous in clean applications in the food and pharma Industries. The DRYHEATER can be optionally offered in sanitary polish or pharma grade piping for individual applications.

2. There is no liquid-based heat transfer medium such as a water bath or thermic oil baths. The heat transfer medium is solid aluminium or bronze. This gives an advantage of the ability to go to higher temperatures than what a liquid medium would permit.

3. Unlike normal process heaters the fluid medium can travel at a high velocity inside the heater which increases the heat transfer rate.This enables the DRYHEATER to be mounted on line in process piping as an on-line heater on demand.

4. The entire heater being built in a solid state permits high pressure applications of upto 150 Bar which would not be possible with normal electric process heaters. This feature makes it ideal for application in heating of cryogenics and other high-pressure gases.

CONSTRUCTION

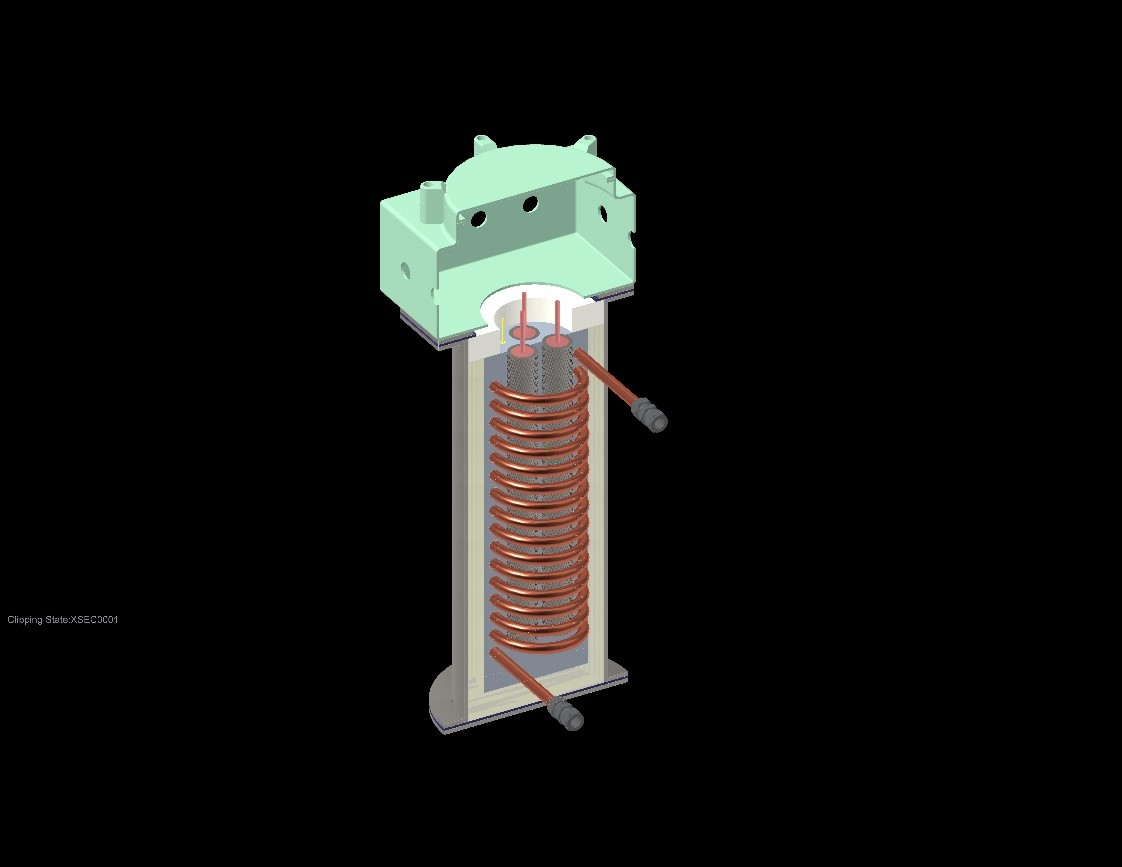

The Dry heater consists of a helically coiled tube or pipe which is cast into a solid aluminium body. The helical coil provides the flow path for the fluid to flow through the heater.

The coil may be constructed out of stainless steels or exotic alloys such as Monel/Hastelloy/Titanium depending on the application. Solid state heaters are also cast into the aluminium body creating a completely solid to solid heat transfer interface in the heater. However, with IEC’s innovative design, it is possible to replace the heaters at the end of their design life with new heaters.

The Dryheater comes with an integrated thermocouple as a standard which regulates the temperature of the heat transfer medium of aluminium/bronze.